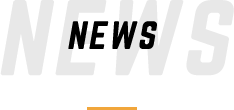

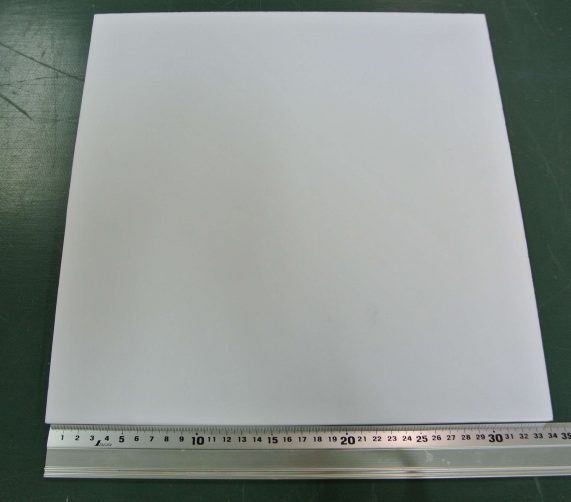

1. Introducing Our Innovative Heat and Insulation Sheet: Melamine Sponge + Aluminum Foil

At Luck Design, we’re excited to showcase our cutting-edge product – the Heat and Insulation Sheet. This remarkable solution is a result of meticulous engineering, combining the excellent insulating properties of a melamine sponge with the heat-shielding capabilities of aluminum foil, all securely bonded together with high-quality silicone adhesive.

2. Unparalleled Thermal Efficiency

Our Heat and Insulation Sheet boasts a thermal conductivity rating of 0.035W/m・K, making it exceptionally efficient at managing heat. It effectively minimizes heat transfer, making it a fantastic choice for a wide range of applications.

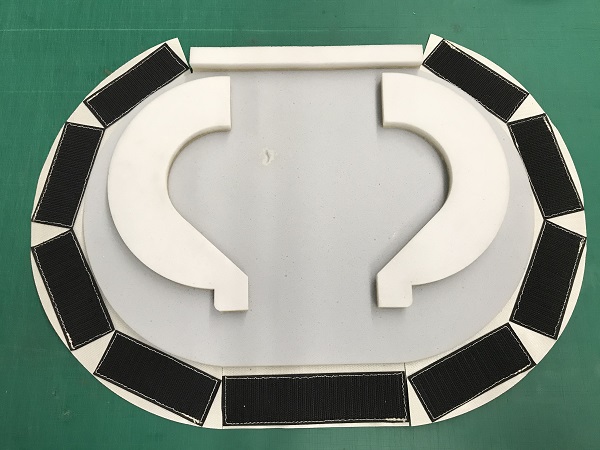

3. Customizable to Perfection

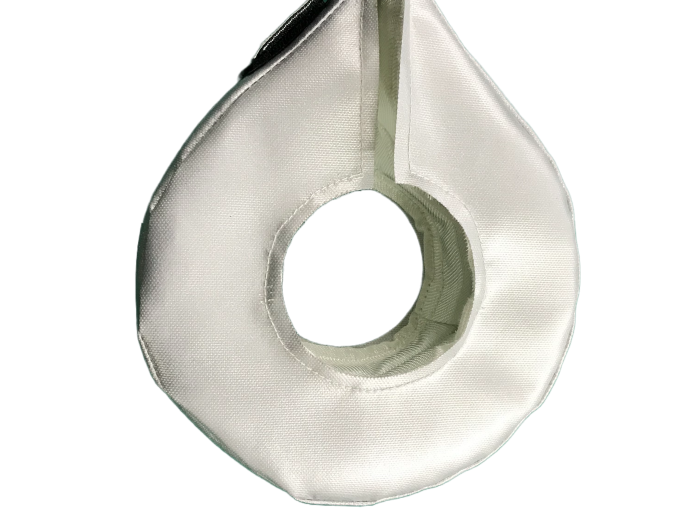

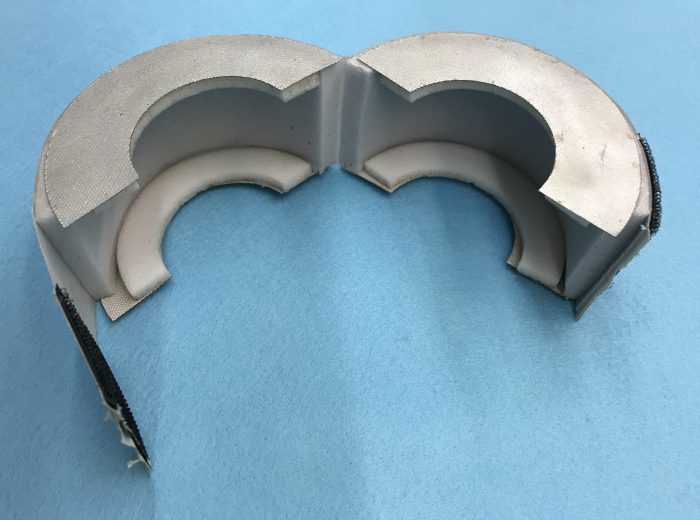

One of the standout features of this product is its versatility. You can easily customize it to suit your specific needs by using standard cutting tools like cutters. Additionally, its flexible nature allows it to conform seamlessly to complex shapes, making it ideal for insulating and shielding pipes.

4. Tailored to Your Needs

At Luck Design, we understand that every project is unique. That’s why we offer the option of tailoring this product to your exact specifications based on provided drawings. We can even incorporate detachable features such as Velcro or hooks to ensure seamless integration with your specific requirements.

5. Versatile Applications

Our Heat and Insulation Sheet is not limited to a single industry. It finds applications in various sectors, including:

a.Clean Room Environments: Maintain precise temperature control and insulation with ease.

b.Food Processing Facilities: Keep perishables at the right temperature while conserving energy.

c.Medical and Pharmaceutical Contexts: Ensure the safe storage and transportation of sensitive materials.

6. Optimal Performance

This innovative product excels at reducing surface temperatures, effectively lowering them from 70°C to below 40°C. The aluminum foil component acts as a barrier, preventing heat radiation and enhancing overall comfort. This also translates to substantial energy conservation, which can lead to cost savings for your operation.

7.Product Specifications:

^Standard Size: 1200mm x 1000mm x Thickness 15mm

^Foil Overhang: 50mm

We are committed to providing you with high-quality solutions that meet your specific needs. If you’re ready to experience the benefits of our Heat and Insulation Sheet in your industry, get in touch with our team today. We are here to assist you every step of the way, from customizing your order to ensuring its seamless integration into your projects. Trust Luck Design for innovative solutions in heat management and insulation.